- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-15 Origin: Site

Lead screws are essential components for power transmission and precise linear motion.The manufacturing process directly impacts their performance,accuracy,and cost-effectiveness.Cold rolling,turning,and grinding represent the 3 primary methods,each offering distinct advantages.Understanding their differences is critical for selecting the optimal leadscrew for your application.

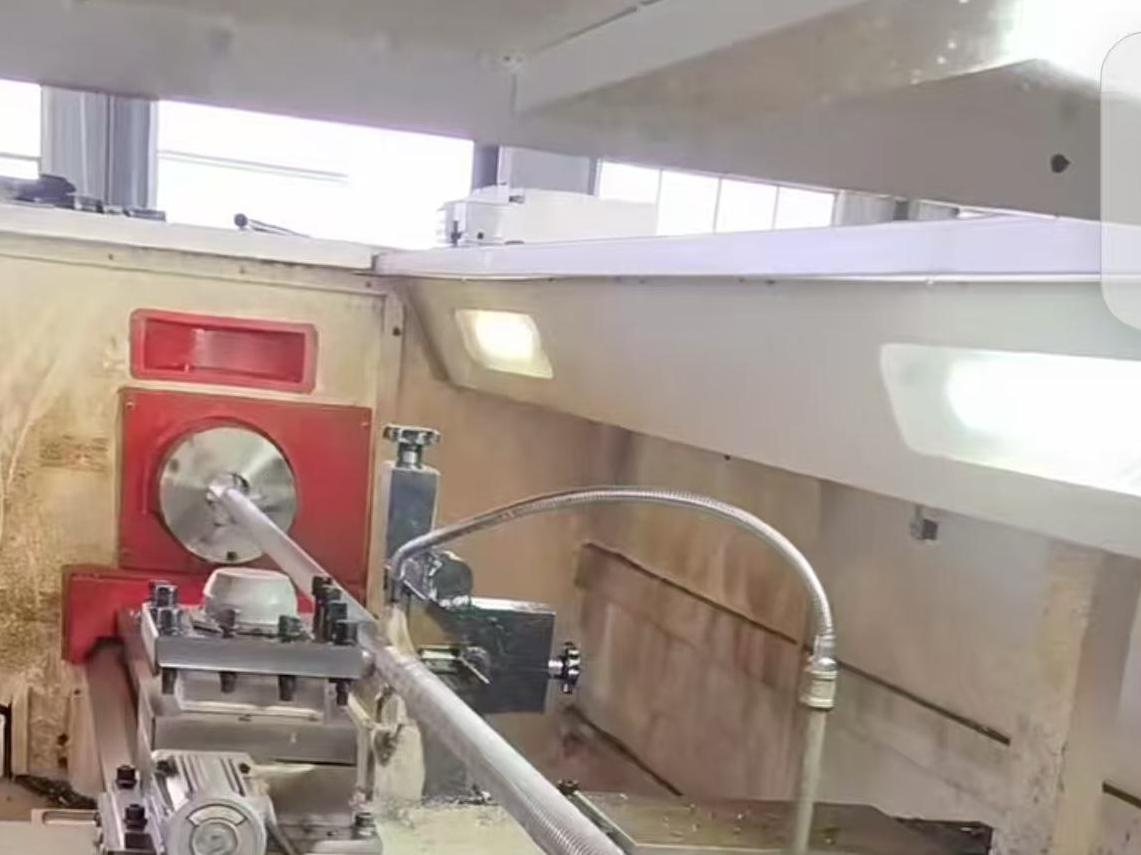

Cold rolling utilizes precision profiled rollers to plastically deform a softened(spheroidized)round steel bar at room temperature.As the bar rotates under extreme pressure,the surface metal flows to form threads without material removal.

Key Advantages:

Superior Cost Efficiency:Near 100% material utilization(no swarf),rapid cycle times,and low unit costs make it ideal for high-volume production.

Enhanced Surface Properties:The work hardening effect during rolling increases surface hardness,density,and wear resistance,while achieving excellent surface finish (typically Ra 1.6-3.2 μm).

Increased Strength: The work-hardened layer and continuous grain flow improve fatigue strength and load capacity.

Consistency and interchangeability:The same batch of products has the characteristics of dimensional consistency and good interchangeability,which makes it easy to assemble in batches.

Turning involves machining screw threads directly from solid bar stock using a forming tool or CNC-controlled toolpath on precision lathes(e.g.,CNC lathes,lead screw lathes).This is the most traditional and flexible approach.

Key Advantages:

Unmatched Flexibility:Capable of producing lead screws with virtually any specification,lead,number of starts,or thread direction.Ideal for custom,large-diameter,large-lead,low-volume,or exotic material requirements.

Controlled Precision:Modern CNC lathes achieve high precision(typically IT7-IT8 grade),suitable for most industrial applications.

Broad Material Compatibility:Not limited by material ductility;can machine almost any machinable metal.

Economic for Prototypes/Low Volumes: Eliminates need for expensive custom rolls,offering cost advantages for small batches.

Grinding is a finishing or ultra-finishing process performed on precision thread grinders.A profiled grinding wheel refines the threads of pre-turned or pre-rolled lead screws.

Key Advantages:

Highest Precision & Surface Quality: Delivers the tightest tolerance and lowest surface roughness(Ra ≤ 0.4,often ≤ 0.1).Critical for minimal friction,high efficiency,and longevity.

Perfect Thread Form Consistency:Precisely corrects errors from prior operations,ensuring exceptional geometric accuracy(e.g.,flank angle,lead error).

Stress & Burr Removal:Eliminates surface stresses and micro-burrs from previous steps,enhancing stability and reliability.

Hardened Material Capability:The only practical method for finishing hardened alloy steel screws,combining high hardness with extreme precision.

Whether your application demands cost-efficient cold-rolled leadscrews,highly flexible turned lead screws,or ultra-precision ground lead screws,LMT is your trusted expert partner.As a specialized manufacturer in lead screws,LMT delivers core advantages:

Full Process Capability:Advanced cold rolling lines,high-precision CNC turning centers,and state-of-the-art thread grinders enable us to select or combine the optimal process based on your needs (performance,accuracy,cost,lead time).

Deep Technical Expertise:Our engineering team masters material properties and process nuances,ensuring precision control from raw material selection to final inspection.

Rigorous Quality Control:Comprehensive quality management systems and precision metrology equipment(e.g.,profilometers,length measuring machines)guarantee leadscrews meet or exceed specifications.

Customized Solutions:Expertise in providing tailored solutions for non-standard designs and unique precision requirements.

Leverage our professional manufacturing technology for a solid foundation in your motion control applications!