- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

Lifting columns leverage advanced linear drive technology,converting the rotational motion of motors into linear motion of push rods through precision mechanical structures.This enables smooth,precise height and position adjustments for various equipment,furniture,or workstations.Typically composed of multiple telescoping sections,these devices extend or retract flexibly as needed,ensuring controlled,seamless vertical movement.Lifting columns find extensive application in ergonomic furniture such as sit-stand desks and adjustable workstations,medical equipment(including examination tables and dental chairs),and numerous industrial scenarios requiring height adjustability.They play a crucial role in enhancing comfort and work efficiency.

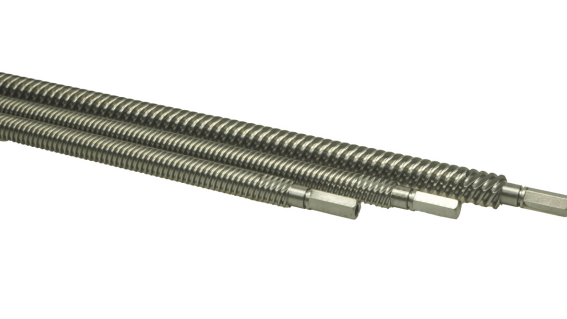

In the field of lifting columns,LMT leverages its extensive technical expertise to offer a range of high-performance lead screw products,which have been successfully deployed in numerous major projects.Our product line encompasses multiple lead screw specifications: Tr12*10 lead screw,Tr14*16 lead screw,Tr12*12 lead screw,Tr12*11 lead screw,Tr10*10 lead screw,Tr10*16 lead screw,Tr14*9 lead screw,Tr10*15 lead screw,Tr23x10 lead screw,Tr37x6 lead screw,and more,covering a wide range of application requirements.

Among these,the hollow aluminum lead screw stands as one of LMT's core products,boasting unique design and material advantages.This product not only enables single-section lead screw transmission but also allows for the assembly of a second lead screw within its hollow interior,forming a dual-section transmission structure that significantly expands its flexibility and load-bearing capacity.The aluminum alloy material is not only lightweight and high-strength but also aligns with green,low-carbon living concepts,contributing to sustainable development.

Additionally,LMT's lead screw assemblies,specifically engineered for electric height-adjustable desks,utilize a dry-film nano-material cooling roll-forming process.This results in a high surface finish and exceptional wear resistance,with load capacities ranging from 80kg to 150kg.These lead screw assemblies ensure stable operation under varying load conditions.

LMT remains committed to providing customers with professional linear drive solutions through innovative technology and reliable products,enabling smarter,more user-friendly height adjustment experiences across diverse applications.