- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

Although lead screws have disadvantages such as lower transmission efficiency and slower movement speed compared to ball screws,they are still used in many semiconductor manufacturing equipment due to the unique requirements of the semiconductor industry.

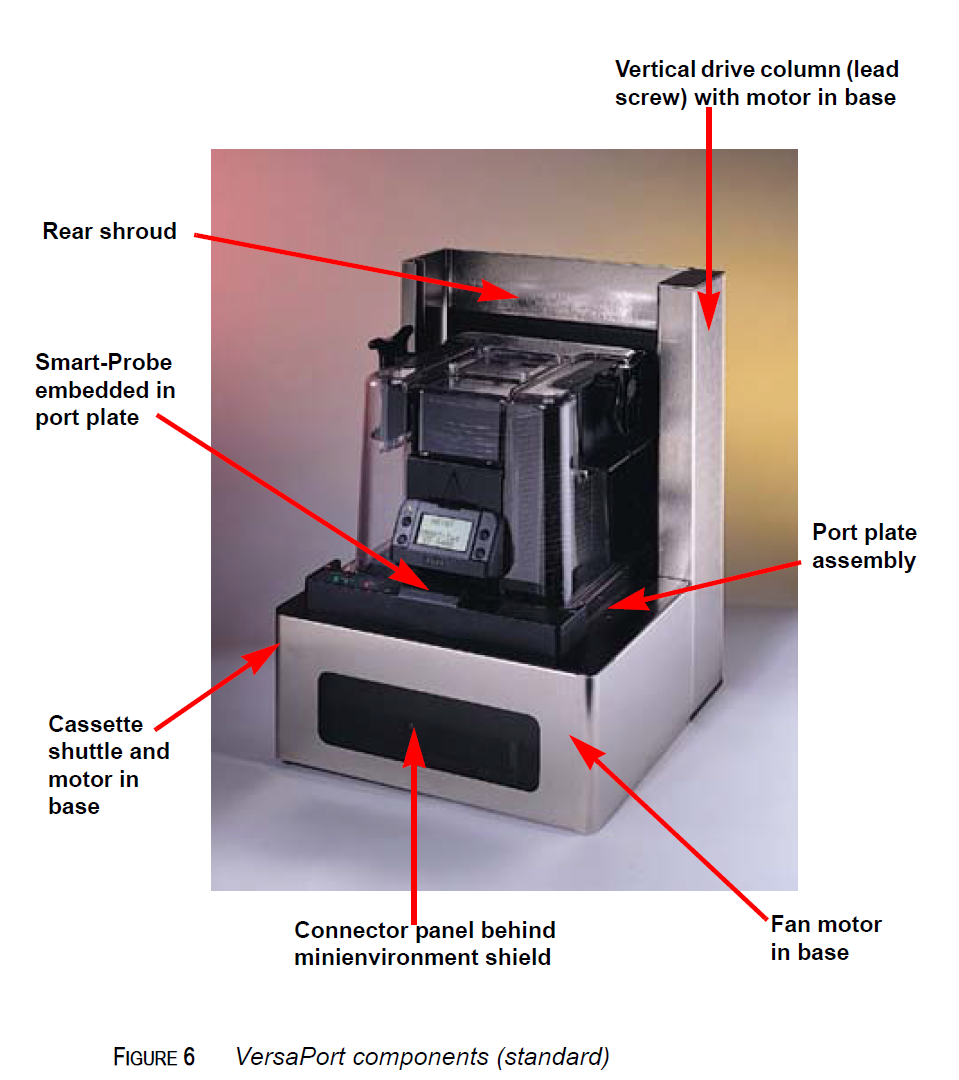

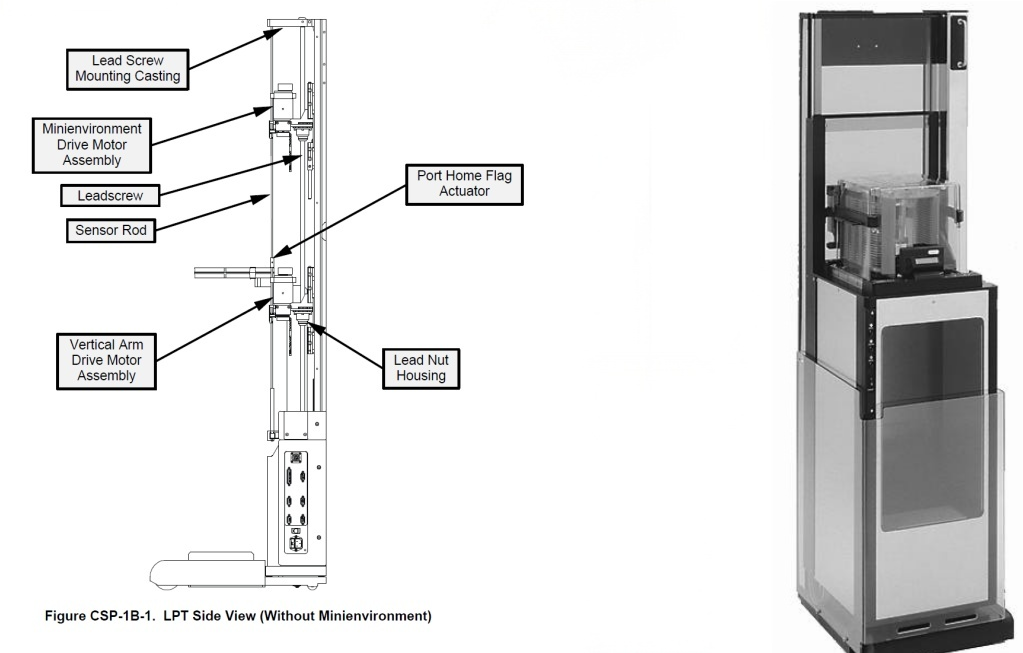

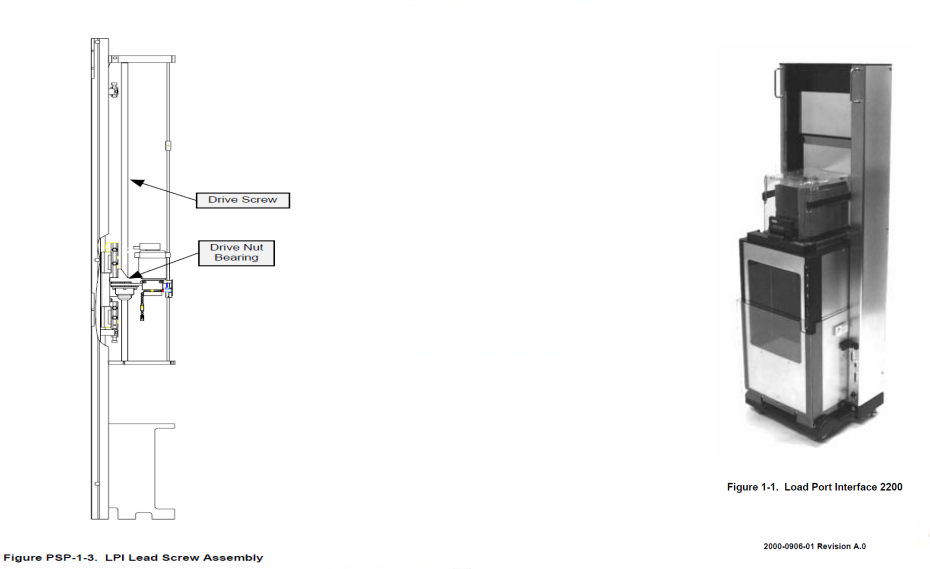

A key example is their use in the SMIF Opener,which is essential for 8-inch wafer production.The lifting system in the 8-inch SMIF Opener from the renowned semiconductor equipment manufacturer Asyst Technologies,Inc.relies on a lead screw as its core transmission component.Representative models from Asyst,such as the VersaPort 2200,LPT2200,and Indexer 2200,primarily function to open the 8-inch SMIF Pod and separate the pod shell from the wafer cassette vertically.This allows a wafer robot to pick and place wafers from the cassette.In this equipment,a motor drives the lead screw to rotate via a timing belt,resulting in the precise vertical movement of the cassette.

Since this equipment operates in a cleanroom environment,the lead screw must meet specific critical requirements:

Minimized Lubricant Use to Prevent Particle Generation:To prevent particle contamination,the use of lubricating grease should be avoided where possible.If lubrication is necessary,cleanroom-compatible grease must be used.In this specific application,the lead screw usually features a carbon steel construction with a Teflon coating,while the nut is made of POM(Polyoxymethylene)material containing PTFE.This material combination ensures smooth operation without requiring external lubrication.

Self-Locking Capability for Vertical(Z-axis)Use:The vertical orientation of the movement requires a self-locking feature to prevent the cassette from falling due to gravity when the motor is off.The inherent design of the lead screw provides this necessary self-locking property.

High Precision by Eliminating Axial Backlash:To meet the precision requirements of the application,axial backlash in the lead screw must be eliminated.This is achieved by using a anti-backlash nut,which ensures positioning accuracy.

The lead screws used in these applications are primarily custom-threaded arc lead screws,such as Tr9.525x5.08,Tr6.35x6.35,and Tr12.7x5.08 lead screw.This arc thread profile effectively reduces friction and increases service life.

When your equipment faces similar challenges,LMT is your ideal partner.We specialize in providing customized lead screw and nut solutions for the semiconductor industry,designed to meet these exacting requirements while delivering significant commercial advantages.By choosing LMT,you can reduce your costs by 20% to 50% and benefit from accelerated lead times of just 7 to 15 days,without compromising on performance or reliability.