- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-03-04 Origin: Site

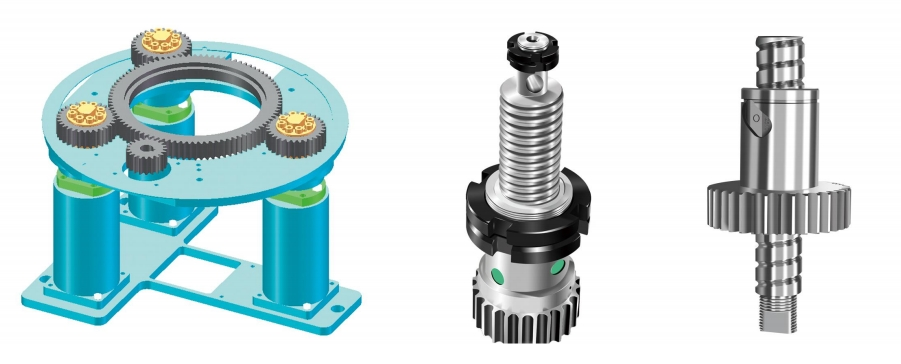

Lifting AGV robots are a common type of automated logistics equipment currently used in manufacturing enterprises,primarily for material transportation and handling tasks.As a key transmission component of lifting AGV robots,the ball screw or lead screw offers advantages such as low resistance,high transmission precision,and fast response speed.

The screw drive system of a jacking AGV robot typically consists of components such as a motor,reducer,lead screw or ball screw,and linear guide.During operation,the motor activates and converts high-speed rotation into low-speed,high-torque output via the reducer,driving the screw to perform linear motion and thereby achieving material lifting and transportation.The ball screws or lead screws are components that convert rotary motion into linear motion.The linear guide rail serves a guiding function,restricting the motion path to ensure stable operation.

The operation of the AGV screw is based on the principle of mechanical equilibrium.During movement,the forces acting on the upper and lower ends of the screw must maintain dynamic balance.When the upward force exceeds the downward force,an upward torque is generated,propelling the material upward;conversely,a downward torque is produced,enabling the material to descend.Through the continuous and controllable rotation of the motor,precise vertical movement of the screw and material positioning can be achieved.

To ensure the efficiency and reliability of the screw drive system in jacking AGV robots,regular maintenance must be performed.Keep the screw clean and dry to prevent dust or moisture intrusion that could compromise performance.Periodically inspect thread wear and replace the screw promptly when necessary.Additionally,check the connection status of transmission components such as screw supports,linear guide,and couplings to ensure no loosening occurs.

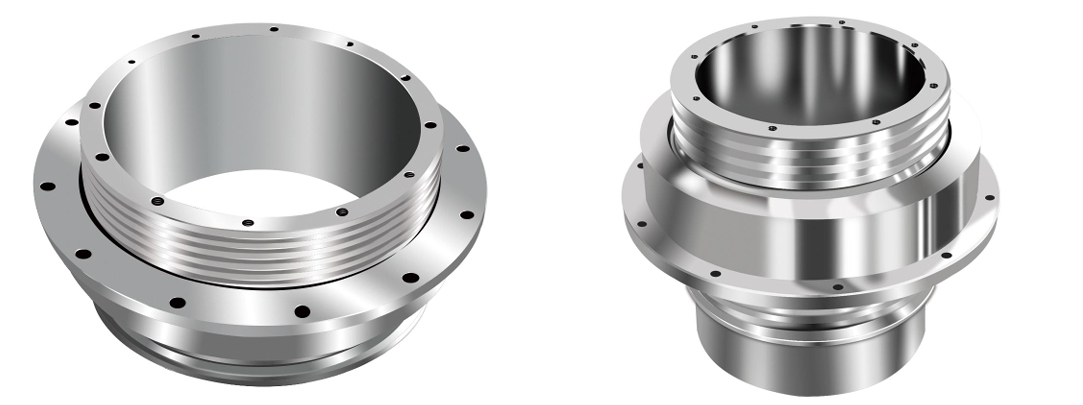

LMT specializes in the R&D and production of linear motion components.The company possesses independent R&D capabilities for ultra-large-diameter hollow thin-walled silent AGV lifting lead screws or ball screws,achieving standardized and mass production of this type of screw.

Multi-lift Screw mechanism

Single-Lift Screw Mechanism