- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

In the semiconductor industry,the handling of wafers demands exceptional precision,smoothness,and reliability.As the foundation of chips,wafers are transported between hundreds of process steps,a task performed by highly specialized Wafer Handling Robots.Within these complex systems,the high precision ball screw serves as the critical actuating component that enables their accurate and stable motion.

Wafers are delicate and valuable substrates.Any vibration,shock,or positioning error during transport can lead to catastrophic yield loss.Therefore,the robots responsible for their movement must provide:

Exceptional Positioning Accuracy:Ensuring wafers are placed into process tools and cassettes with flawless repeatability.

Smooth and Stable Motion:Achieving jerk-free movement during acceleration and deceleration to prevent stress on the wafer.

High Reliability and Durability: Supporting continuous 24/7 operation in demanding cleanroom environments.

These stringent performance requirements are ultimately met by the robot's core mechanical drives,most notably the component governing vertical travel—the Z-axis.

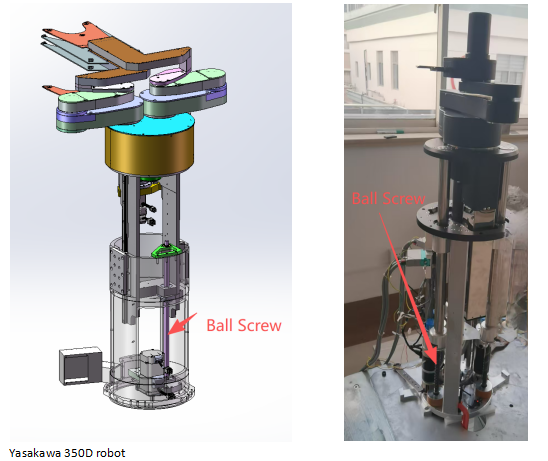

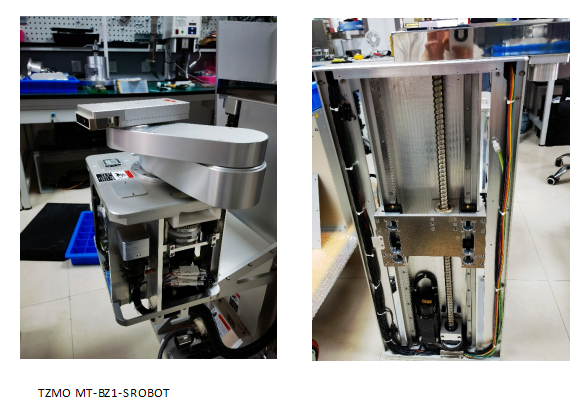

Across various wafer robot architectures—including R-Θ and SCARA types—the presence of a Z-axis for vertical lifting and lowering of the end effector necessitates the use of a vertically mounted precision ball screw.Leading wafer robot manufacturers such as Yaskawa,Kawasaki,TZMO,and JEL consistently integrate high-precision ball screws as the core drive component in any of their designs featuring a Z-axis.

Its key functions include:

Precise Motion Conversion: The ball screw efficiently converts the servo motor's rotary motion into the exact linear motion required for the end effector's vertical travel.High-quality screws provide minimal backlash,which is essential for precise position control.

Ensuring Smooth Vertical Travel: The pick-and-place sequence requires the end effector to gently lower to grasp a wafer and smoothly lift to release it.The performance of the ball screw directly determines the smoothness and consistency of this critical action.

Delivering Rigidity and Load Support:In its vertical orientation,the ballscrew must support the combined weight of the end effector and the wafer while maintaining stability under dynamic loads.A high-rigidity ball screw is fundamental to the system's structural integrity and positioning accuracy.

Selecting a reliable component supplier is crucial for maximizing equipment performance and ensuring on-time delivery.LMT,as a specialized ball screw manufacturer,understands the critical needs of the semiconductor industry.

We provide tailored solutions for semiconductor equipment builders:

Comprehensive Product Portfolio:We offer both high precision ground ball screws for the most demanding applications and rolled ball screws for cost-effective solutions without compromising on performance.

Wide Diameter Range: Our products cover diameters from 3mm to 80mm,accommodating the design requirements of various wafer handling robots,from compact to large models.

Competitive and Reliable Lead Times: We prioritize fast turnaround to keep your projects on schedule,offering a 7-day lead time for rolled ball screws and a 25-day lead time for ground ball screws.

Expert Technical Support: Our engineering team is ready to provide application-specific support,from component selection to integration guidance,ensuring optimal performance in your system.