- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The high-precision ball screw is an indispensable component within wafer handling robots, directly enabling the precise and reliable Z-axis motion that is fundamental to modern semiconductor manufacturing. It is a key enabler of throughput and yield in fab operations.If your wafer handling robots or other semiconductor equipment require high-performance, dependable ball screw solutions, LMT is positioned to be your ideal partner.

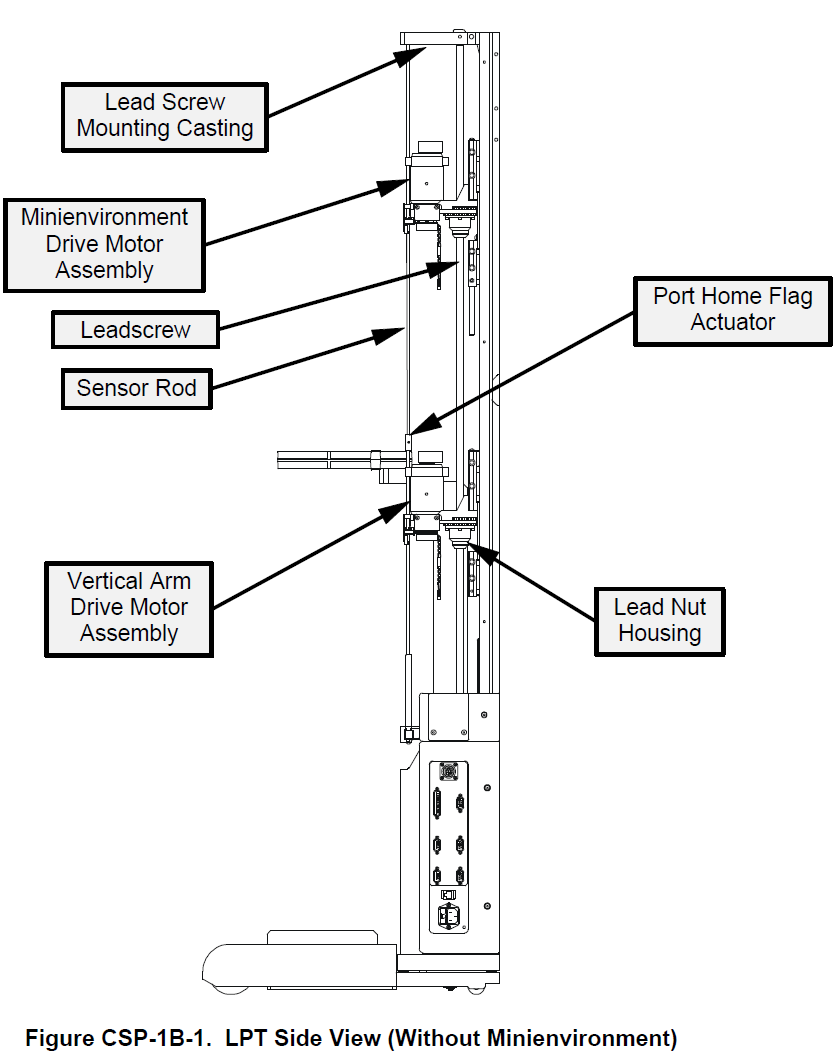

In the field of automation where ultra-high efficiency and speed are pursued, ball screws are typically the preferred choice. However, in the semiconductor industry, which demands ultimate cleanliness, stability, and reliability, the seemingly traditional lead screw, with its unique advantages, plays an irreplaceable role in critical equipment such as SMIF Openers. This article will delve into how lead screws meet the extreme demands of semiconductor manufacturing.

This article introduces LMT's precision lead screw assemblies, engineered specifically for high-performance surgical lighting arms. It highlights key features that address the critical demands of the operating room, including maintenance-free operation with self-adjusting backlash and dry-film lubrication, ensuring precision positioning and eliminating the risk of contamination. The text also emphasizes the components' compact design, exceptional durability, corrosion resistance, and ultra-quiet performance, presenting them as a core solution for reliable, long-lasting, and precise surgical illumination.

Lifting columns leverage advanced linear drive technology, converting the rotational motion of motors into linear motion of push rods through precision mechanical structures. This enables smooth, precise height and position adjustments for various equipment, furniture, or workstations.